A couple of years ago, I got around to making a wall-hanging tool cabinet to store my hand tools. It was made from red oak, with birch plywood for the panels, and while not pretty, did a good job at holding my tools. The design came from the countless other wall hanging tool cabinets I'd seen posted here and there in the world of online woodworking, and I was pretty pleased with the result. Over the following months, I adjusted the tool holders, added more tools, moved other around, and fiddled with it until it became pretty full. More importantly, it became more useful, as I was more comfortable with where everything was stored, it was easy to reach for what I needed, sometimes without looking. It was also easy to know when I had forgotten to put a tool back into place.

But I screwed up on one of the most important things about a tool cabinet - closing the doors. I was so pleased with how the cabinet was set up, and seeing my modest but nice array of tools, that I left the doors open not only when I was working, but also when I was not. I liked walking into the shop for another session, and seeing my tools smiling back at me, all in their nice holders, all in order, ready to go. I felt fine about things. In fact, sometime last year, I'd even purchased one of those rust inhibitor stick-ups, the kind that releases a rust inhibiting vapor, and put it in the case. Of course, those only work in a closed space, and not sitting near my tools in an open cabinet.

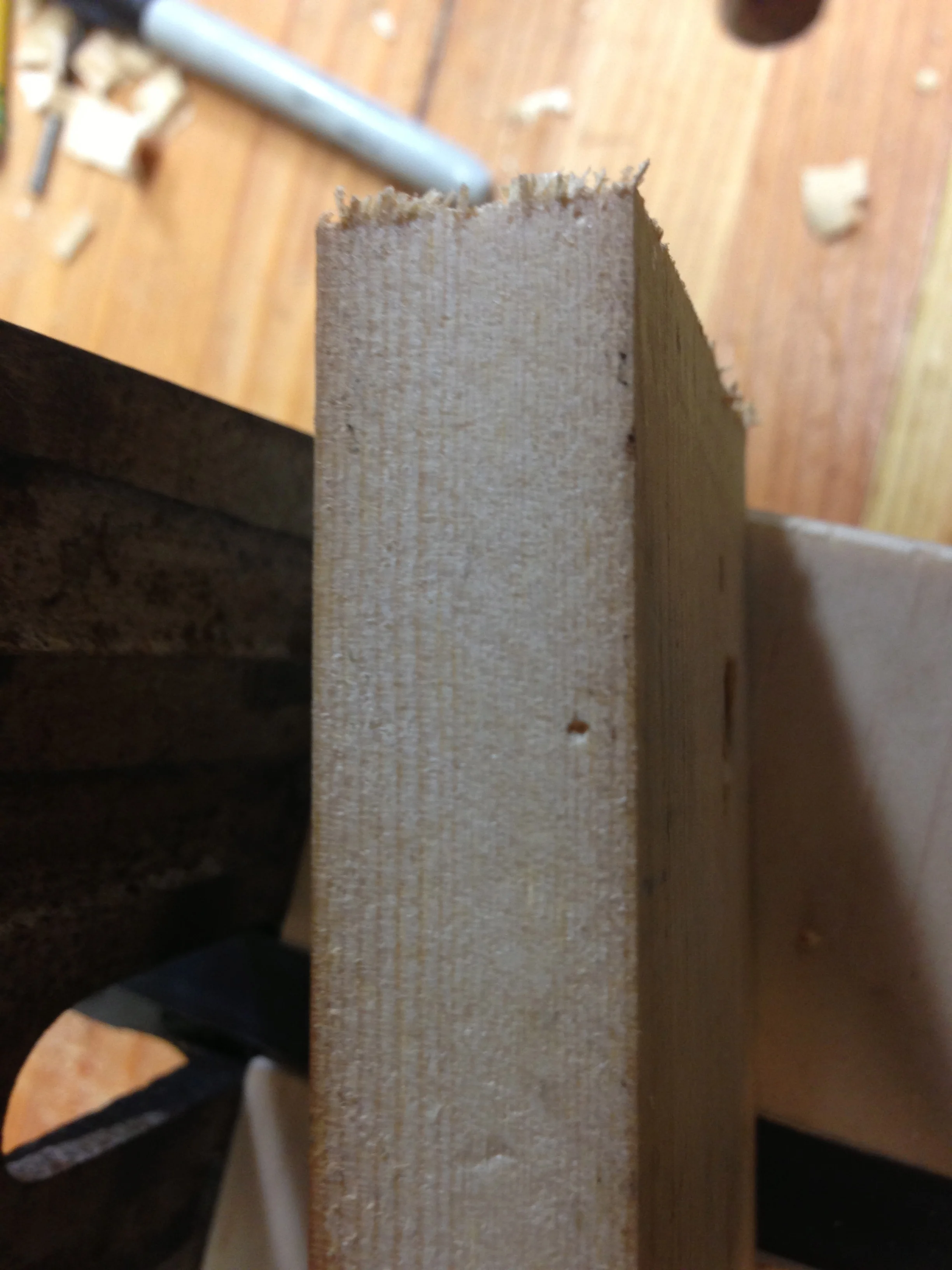

And then, recently, I started to see it: little black spots here and there on a chisel, or the sole of a plane, or the blade of a saw. Where there was once jew a few, after while there were quite a few more, and I realized I was starting to have a rust problem. I knew about the theory of protecting my tools from rust, sure, but in the first several years of woodworking, I really hadn't seen it appear on any of my new tools, or on my used/vintage new-to-me tools, after cleaning the rust off them when first acquired.

Bullfrog vapor corrosion inhibitor

So, feeling like a fool, I resolved to slay the beast. I spent all of one afternoon going over every single tool in the cabinet, removing any rust spots, or soon-to-be rust spots, using an abrasive pad and WD-40, then cleaning the remaining parts of each tool, wiping them all over with a WD-40 covered rag. The proceeded to vacuum out the insides of the cabinet, wiping it down with a tack cloth until it was dust free. And finally, I proceeded to place everything back, and even replaced the long since uselessly depleted Bull Frog vapor corrosion inhibitor. And then I CLOSED THE CABINET DOORS.

That evening, with dirty hands, some messy rags, and feeling stupid, I vowed to not be such and idiot. Not only do I now keep those cabinet doors closed when I'm not using the tools, I also make a point to brush and blow any dust off each tool before I put it away, and wipe the metal surfaces it with an oiled rag - stuff I should have been doing all along. Airborne dust and salt settling on your tools attracts water, and that is where the rust comes in. Its pervasive, and one of the dustier places has to be a woodshop. So, yeah, finally, I'm serious about establishing good habits to keep the rust monster at bay. And I can get by without seeing the spread of nice tools all in a row, knowing they're well protected.

After all, its a tool cabinet, not a tool display case.

Not pretty, and that one door hangs a little crooked, but at least they're closed.