This weekend, humidity in the Chicago area was hovering around 94%, and its been between pretty high for the whole month of August. With extremes like these, it's been a great change to see the effect of wood movement on my past projects, and hopefully learn to better appreciate this unstoppable force.

One of my biggest, and earliest woodworking projects was to build a full set of kitchen cabinets when we re-did our kitchen. The design has 33 cabinet doors, 17 drawers, and face frames, all made from flat sawn red oak (and then the standard plywood boxes and drawer bodies). As this was early in my woodworking journey, I didn't have the level of appreciation for choosing proper grain direction that I do now. The frame and panel doors were made with plywood panels, a few with glass, and stub tenons & grooves (as opposed to full mortise & tenon joinery). The potential was high for them to move over time. But so far, I've been lucky: just a few of the 33 doors have moved a bit. Let's look at them...

This first photo shows the bottom inside edge of this door getting swollen, to the point where some force is needed to close it. It's also tight on the bottom edge. The door facing it is fine, however.

swollen at the bottom, making it hard to close

This pair of doors have also expanded towards each other, making for a tight fit. If I close the tow of them together, they close tightly. If one is closed, I can't close the other.

tight here

can't close one at a time

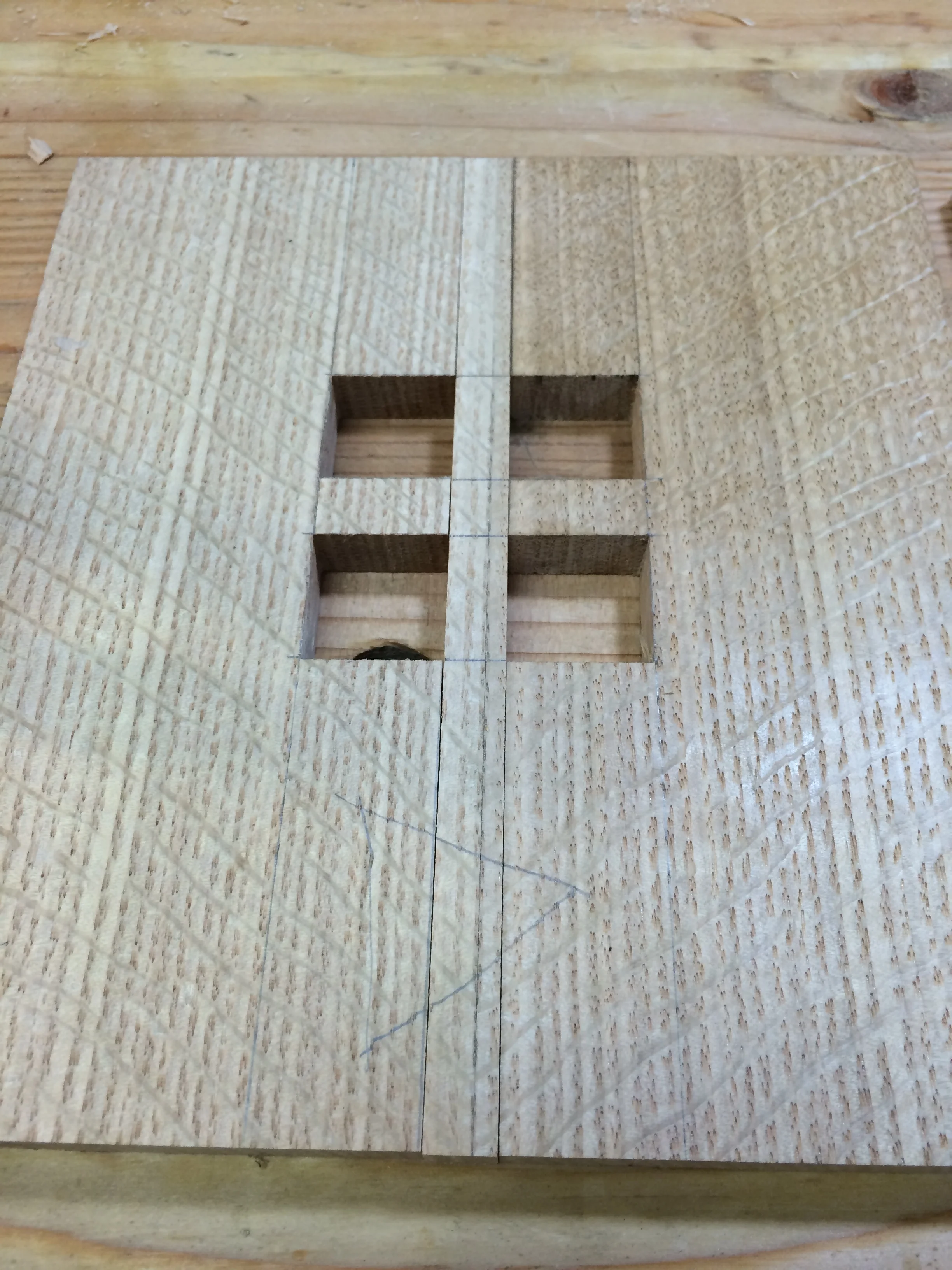

This door has twisted, so that the lower corner is "in" about 1/4" inch.

do the twist

And the rest of the doors and drawers are fine. 4 out of 33 is not bad for blindly picking wood without careful attention to grain. Of these 4, now might be a good time (at the point of maximum expansion) to trim the 3 "swollen" ones down to where they are just barely working smoothly again, knowing that they'll be fine as it shrinks, and for the next time it gets humid again. Now is the time to deal with this, as It's impossible to guess how much of a gap to leave in the dry seasons. For the one door that's twisted, I have to either live with it, or re-make it, this time being conscientious of the material.

Also in the kitchen, we have some birch laminated slabs for the counter tops, and two of them meet at a right angle. In the winter, there is as much as a 3/16" gap at this joint. But now, they are tight. They're only butted up to each other, and attached to the base cabinets with clips, allowing them to move.

that's tight!

Last year, I built a window bench / banquette, with batten supported lid/seats. These were fitting perfectly then, but looking at them today, the tops have moved about 1/4", and now stick out proud from the "side" pieces, who's grain is oriented 90° from the lids...

sticking out

The obvious fix here is to remove the lids from the piano hinges, shave some length off the back (where the lack of finish will not be seen) and re-attach them. I think I'll have to be careful not to cut them perfectly flush now, as they will shrink again, and be uneven the other direction. I'll have to opt for a happy medium, somewhere in between.

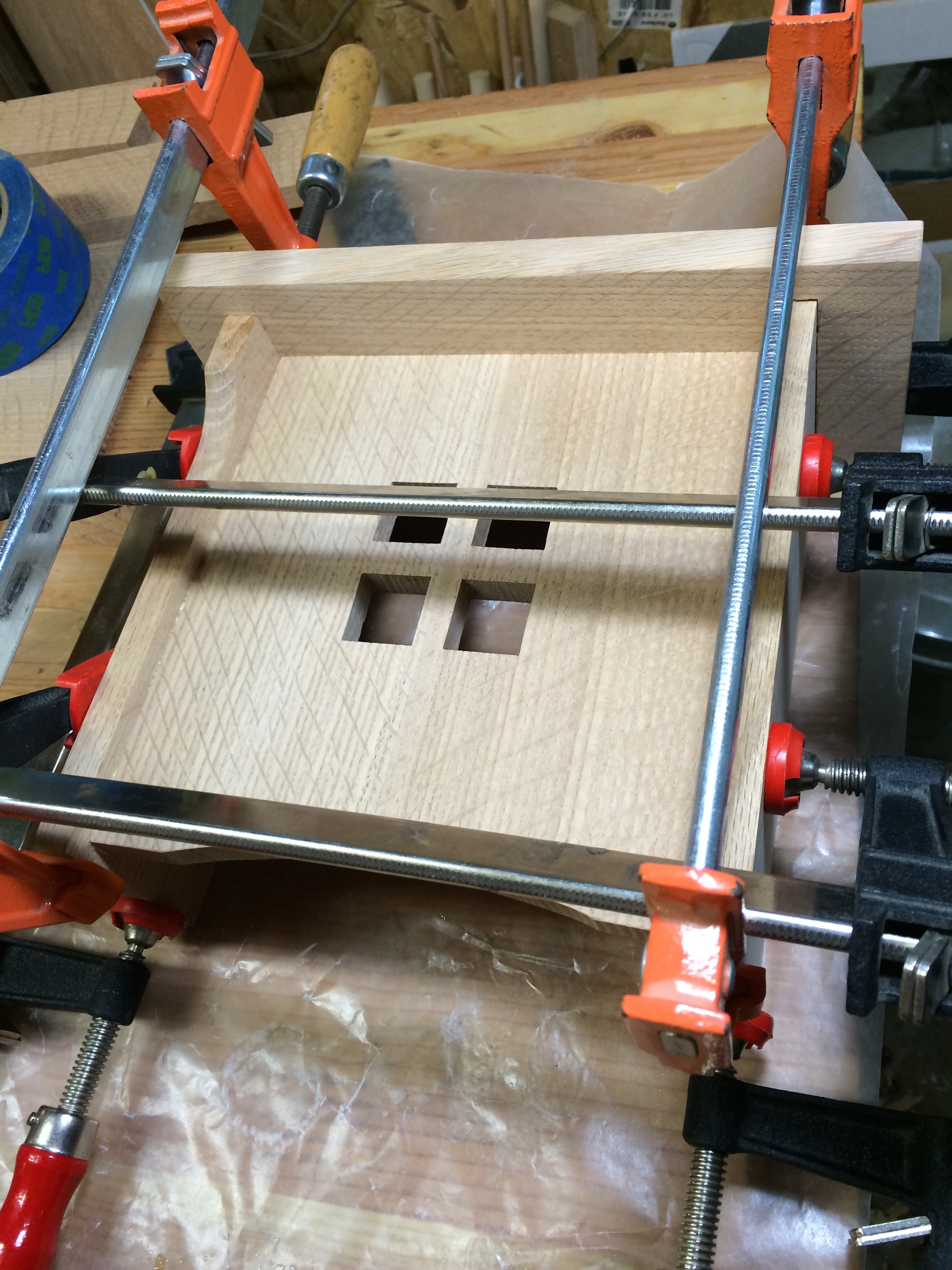

Here's an example of how good design can compensate wood movement. On the mission pedestal table I built last year, the wide tops have indeed expanded. But the movement is only visible where the the edges of the skirts are pushed apart, on the underside edge of the table. The table top still looks good, with the two halves coming together tightly. If I had built the top and skirt to fit tightly during of high humidity, the opposite might have happened during the dry season: the skirt pieces would have been flush, and the gap between the two halves would have opened, which would have been ugly.

a gap, but down where only furniture nerds will see it

The lesson from all this is not to think wood movement is theoretical, or can't happen to you. It's not, it can, and it will. It's therefore a good idea to take the time to examine the things you've built, and take note of how well, or how poorly, your earlier designs have held up under the extremes of humidity, and build your future projects accordingly. I'll revisit this in the middle of winter when things are bone dry, and we'll compare how the piece have moved, looking at both the fixes and the pieces that I left alone. Fingers crossed. However, as we're talking about wood, there's never going to a perfect fit. The wood will move, and our furniture must move with it. Hopefully, joints won't crack, doors won't stick, and boards won't twist, but when (not if) they do, take it into account, and learn from it.